Starting another run of “Ultimate” thread stands and after giving the lathe a through cleaning and oiling we start by prepping the brass rod by turning it down to size before it gets cut into sections.

Once upon a time I cut all these little slugs by hand but the addition of a metal band saw makes the work easier and faster.

After cutting, the brass gets centre drilled for further machining and turned down and squared off as the dimension of the base has to be pretty exact. I made the dial indicator holder on my little mill to measure these cuts accurately.

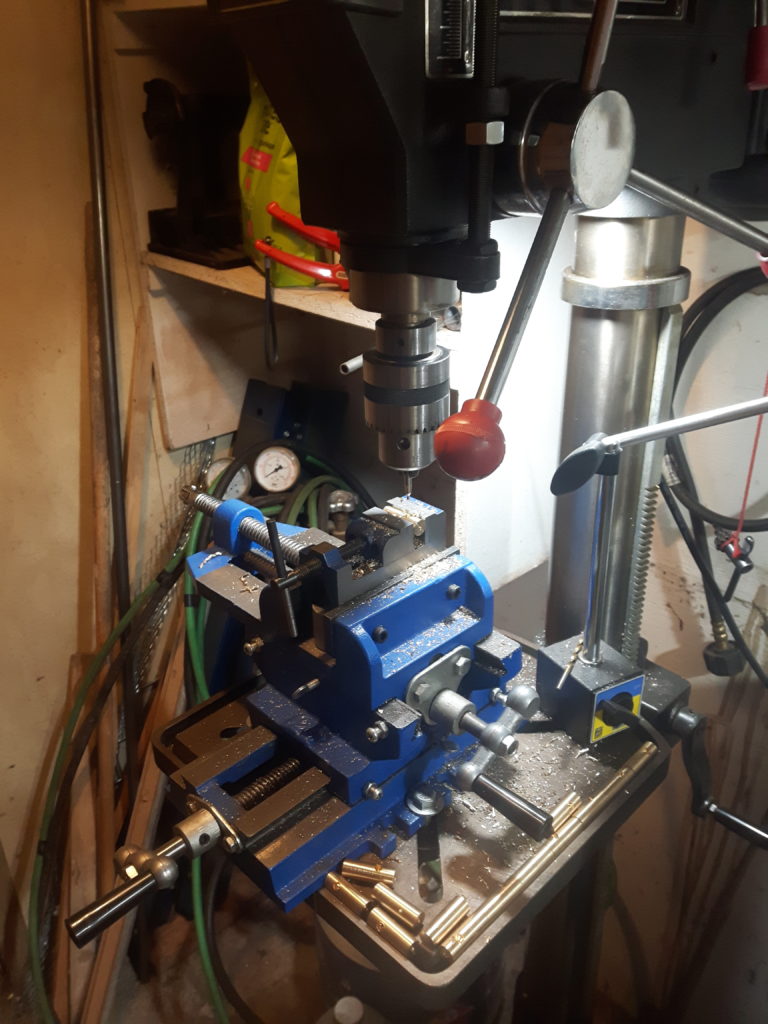

The holes for the thread arm and lower set screw get drilled on the press, the drilling of the longitudinal holes will get done on the lathe since they are just that more accurate.

Stay tuned…