Over the past year, and past few years a lot has changed in our little corner of the world with changes in health, relationships, and most recently the location of our workshop.

Finally have the internet set up here so I can sit at the new desk and for the first time in a long while, post an update.

A year ago I seriously messed up my shoulder in a motorcycle incident and also messed up my right ankle and it was a long path to get back to being functional, and functional enough to get this shop moved. Without the help of some good friends I still don’t think this would have been possible.

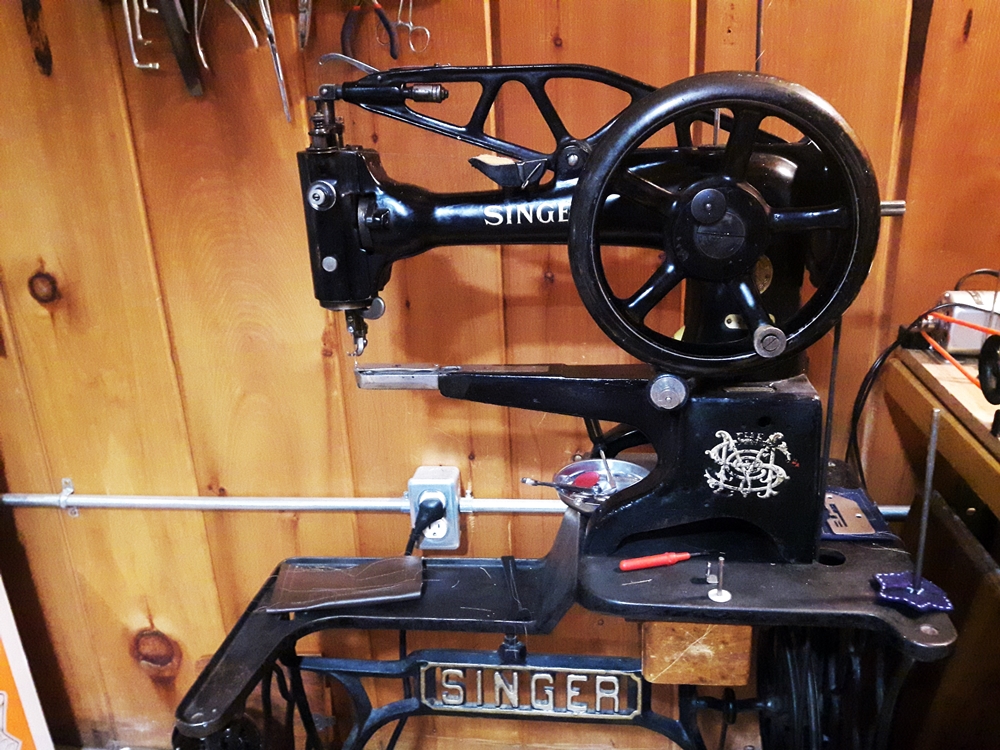

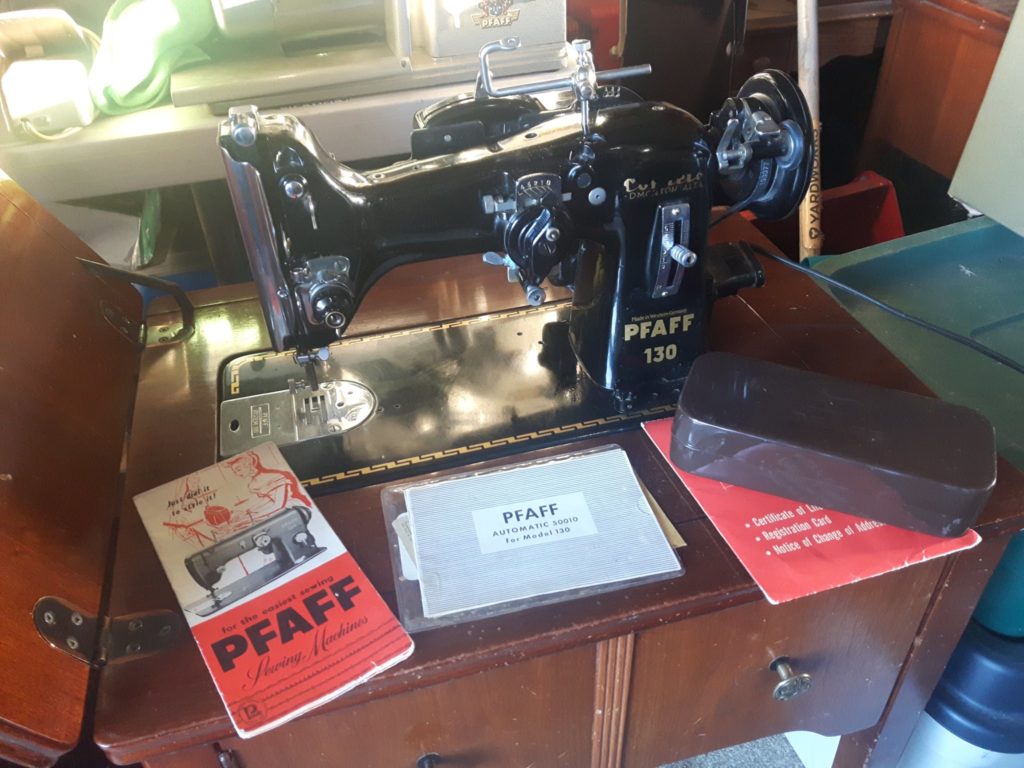

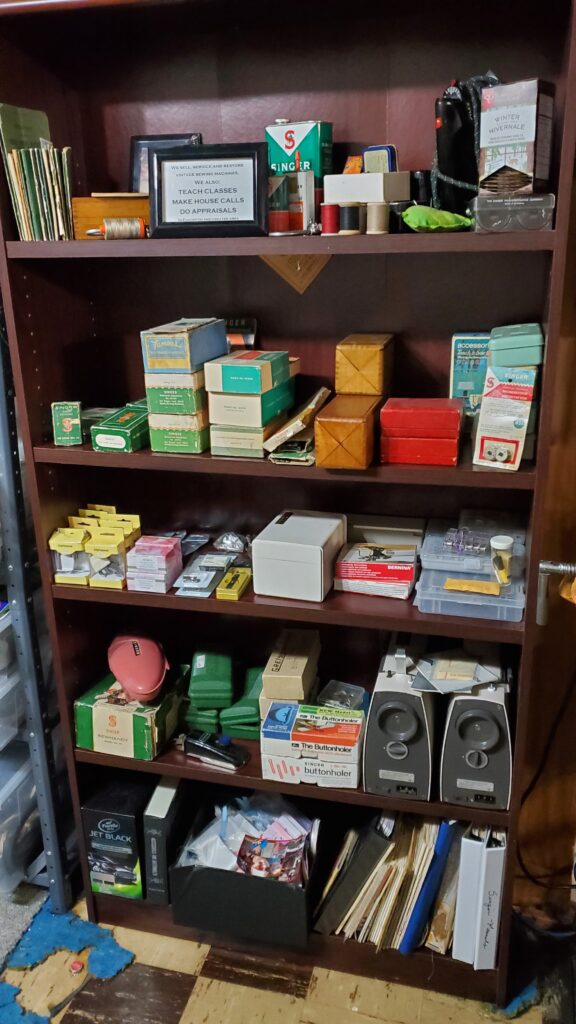

We loaded up three truck loads of machines and tools and this was the smallest load, the thing with sewing machines is that the cases and machines had to sit on the floor and you really could not put anything on top of them.

Being that the new shop space is about half of the old one, I got a storage unit which is only a few minutes away so grabbing machines or parts from there should be pretty fast and easy.

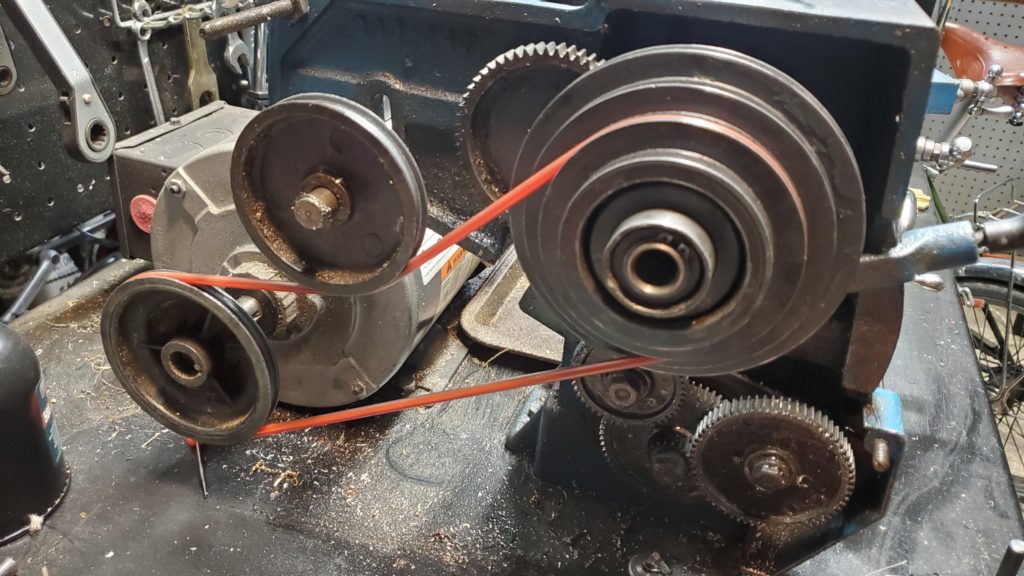

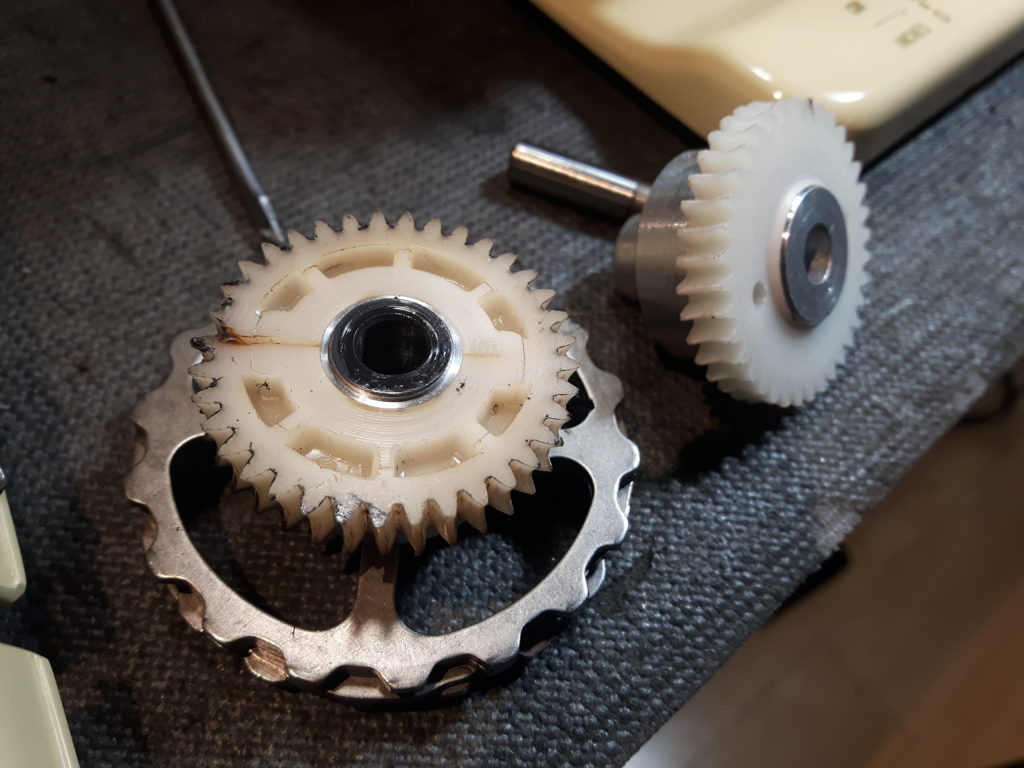

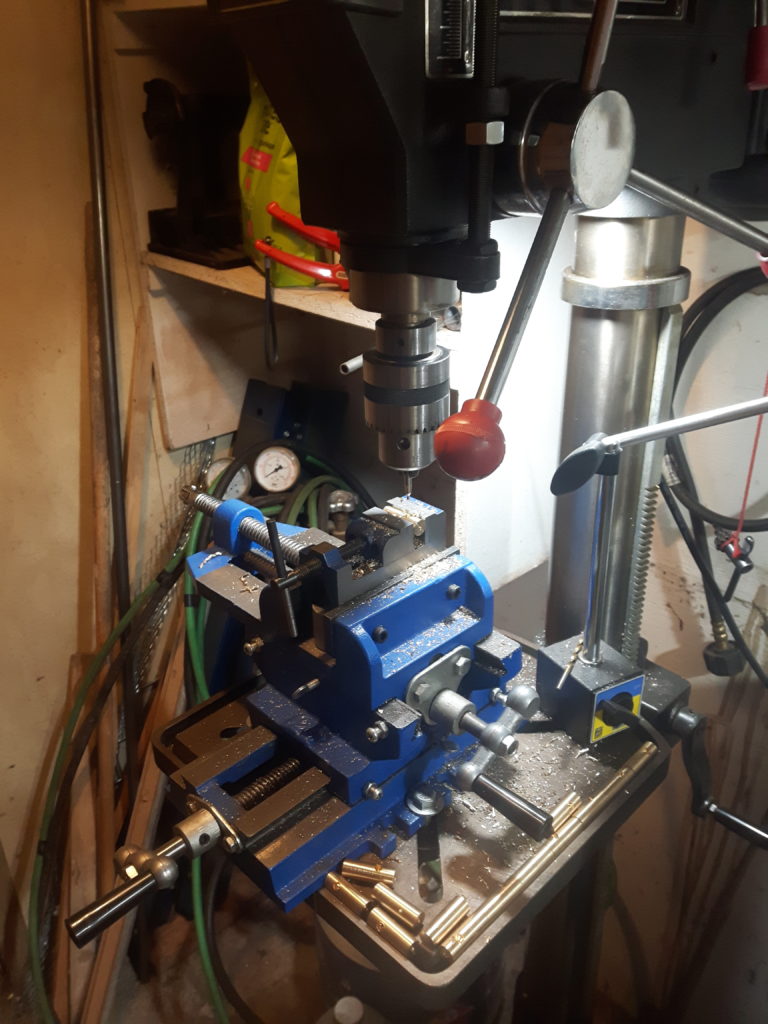

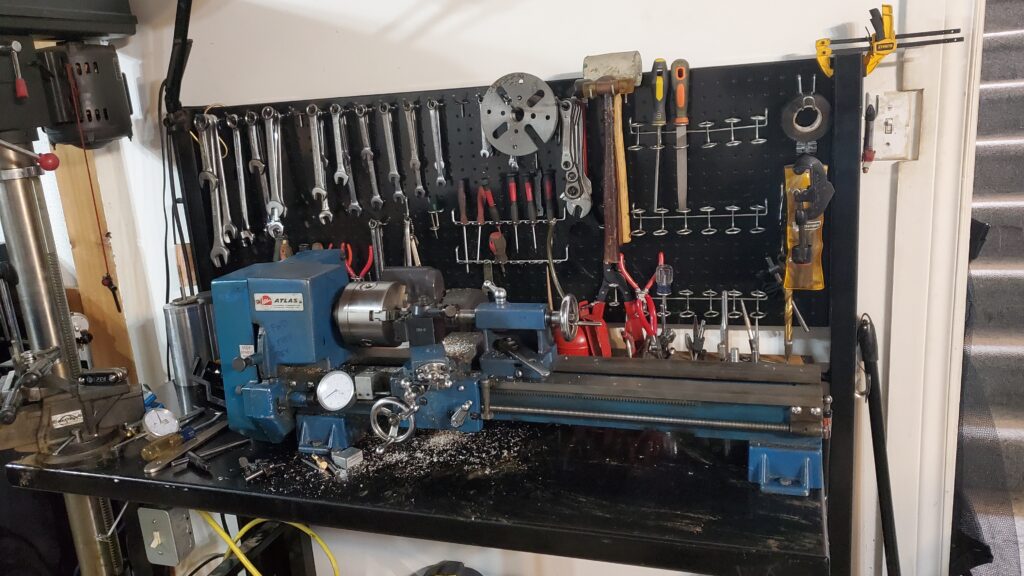

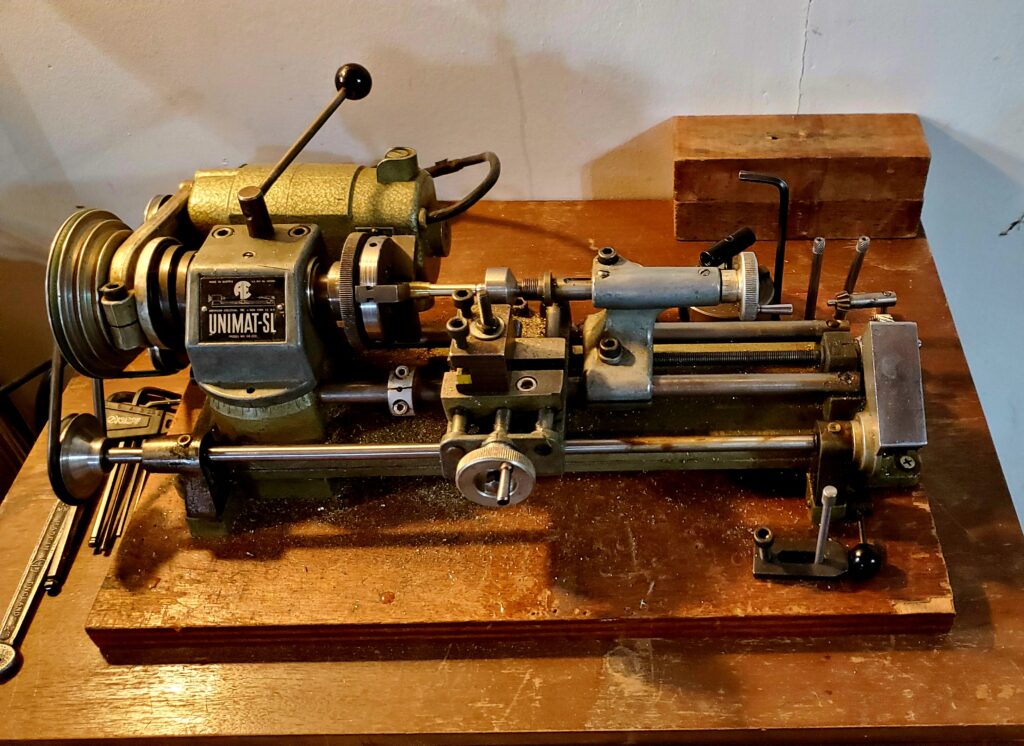

Moving the lathe and tooling was probably the hardest job as it is heavy, awkward, and delicate but it’s all dialled in and ready to do some work as is my little Unimat, which you can carry in one hand.

We are still about a week away from a grand re-opening as besides moving, my partner had to have foot surgery so what would have normally been a vacation was so busy, I need to go back to the side gig at the dealership to get a rest. lol

With that it’s time to get to unpacking more parts and doing more organizing, I am gonna need to pick up more shelves and a rack for new parts to hang .

Happy sewing !