Bernina 217 – Commercial

Within the sewing community there is often a great deal of confusion on what makes a machine an industrial model and many shifty sellers will try an pass off domestic models as being an industrial, sometimes hopping them up with a more powerful motor.

An industrial machine is typically designed to handle a single function in a factory setting, such as bar tacking, and will be fitted to a table with a clutch motor, or overhead belt drives and were designed to run all day, sometimes over three shifts.

This is a Union Special 56400 industrial machine, note the multiple tensions and the oil gauge below the tensions, it is not bigger then a domestic machine but weighs a ton and was designed to run at 3000 stitches a minute all day. These were commonly used in factories where denim jeans were made.

An industrial machine does not have to be heavy duty and be able to sew leather, many are light to medium duty designed to sew lighter fabrics and materials.

The wee Singer 24 was a model that was sold as a domestic and industrial model and was commonly used in the hat making trades as it was capable of sewing at 3000 stitches a minute, and many were configured for special tasks like binding.

A commercial machine is one like the Bernina 217 (shown at the top) or the Pfaff 130, which were offered in commercial / industrial tables with clutch, or direct drive motors, and were cap[able of zig zag and other stitch patterns via use of external cams or in the case of the 130, an automatic stitch attachment, often called a “bread box”.

Pfaff supplied a commercial table with a 3 amp direct drive motor which functions much like a modern servo, and does not run continuously like a clutch motor. These were marketed to tailors and seamstresses who needed a robust high speed machine that could sew all day with few breaks.

Sail makers and riggers favoured the Bernina 217 because it could do the speciality stitches they needed to produce sails.

My Singer 108w20 is an industrial machine, originally designed to sew binding at 4000 stitches a minute, and was rated for medium weight materials like canvas. I have converted it to work as a cylinder arm by modifying the needle plate, and have fitted a 1.3 amp domestic motor. It has a needle feed where the needle also moves the fabric through along with the walking foot and lower feed dogs.

My 1911 Singer 31k20 spent most of it’s life in a local tailor’s shop, making custom suits, tuxedos, dresses, and uniforms… these were also used as industrial straight stitch machines in bigger factories. After 112 years it still sews just as well as it did when it was new and who knows how many millions of stitches this machine has sewn.

Sometimes the lines get a little blurry when you are looking at machines and some companies even add to the confusion, Bernina sold the x50 series machines as “industrie” but they better described as a commercial machine.

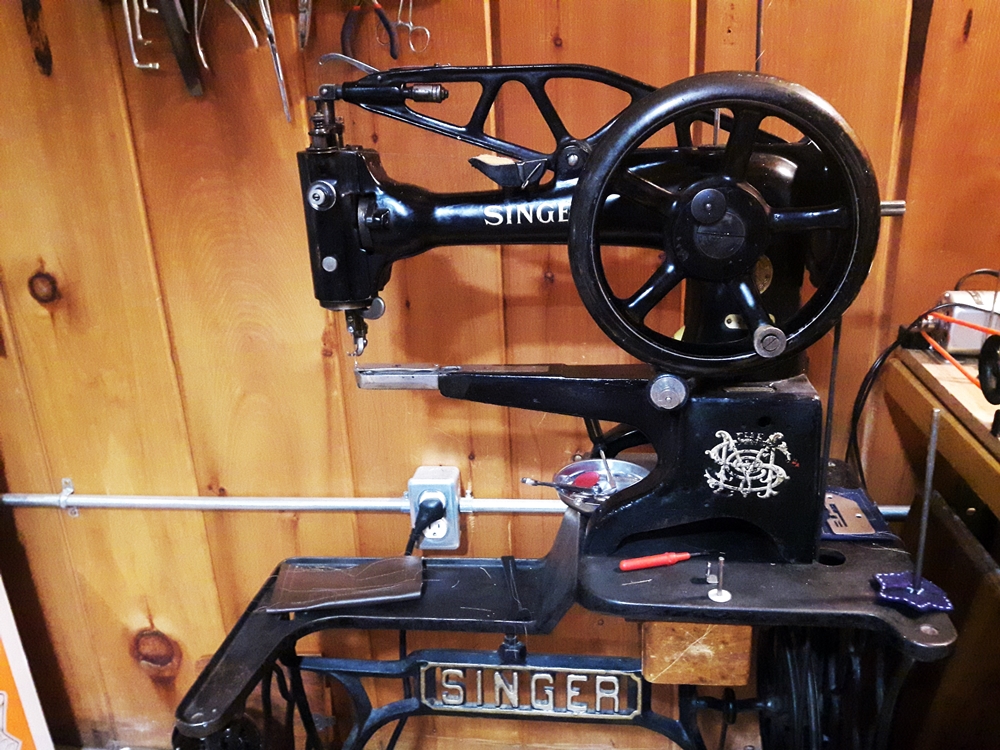

My Singer 29k58 is a cobbler’s machine / patcher so would be defined as a commercial machine, but people often call them industrials.

Happy sewing.