My parents were born in the depression and because I came along late in life feel more like a boomer than anything else, and had parents who repaired, re-used, upcycled, and stretched every penny, and that even applied to my mom and her sewing. She worked as a seamstress to help pay the bills before she went back to school, at 50, to become a nursing aid.

Some folks say, and maybe those are the ones that sell needles, that you should change your needle every eight hours or after every project but if the needle isn’t bent and just has a little burr, you can touch it up.

You can usually hear the needle popping when it has developed a burr before you can see it with the naked eye, and will be most evident when you are sewing lighter fabrics.

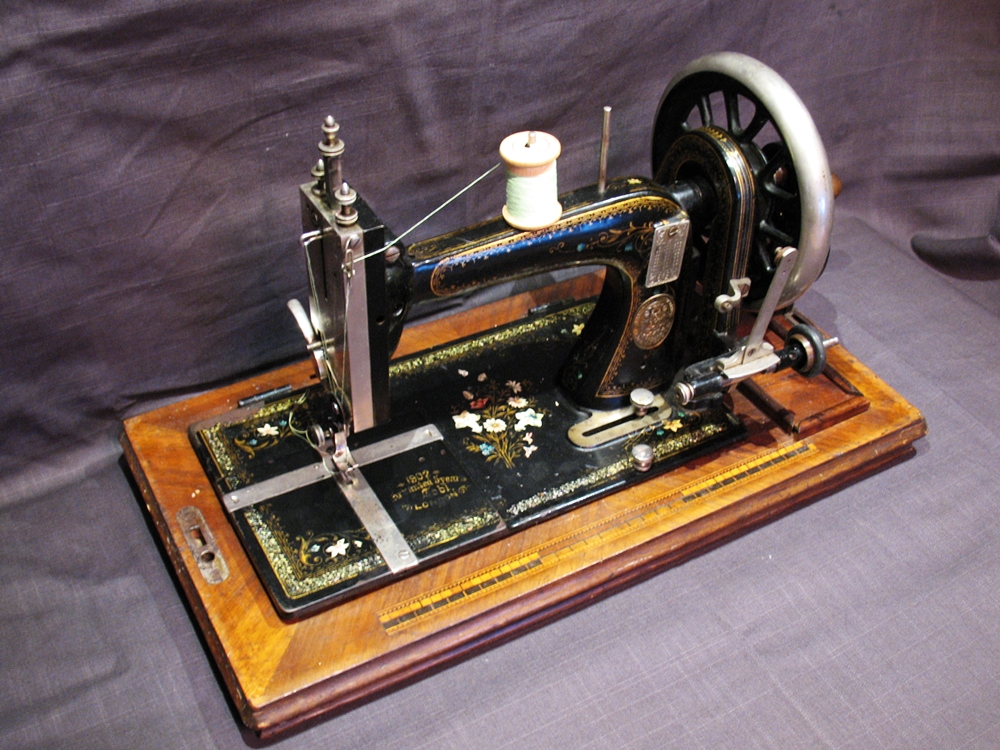

My 1902 Winselmann has an interesting bobbin winder, with an extension to the right of the bobbin tire and this was used to de-burr needles. It just takes a second to do as you wind up a new bobbin.

In the modern day you can use a needle sharpener, as these are still available, or go to a sporting goods store and pick up a fish hook sharpener with a slot, which is normally used for sharpening fish hooks.

A few light passes on the hook sharpener is all it takes and then that needle (this works on normal sharps) will be good for another day of sewing.

The commercial sharper is easy to use, just drop the needle in point first and turn the sharpener a few times.

The hook sharpener… just a few light passes as you turn the needle in your fingers works wonders. It is a diamond grit also used for putting a really fine edge on knives and also touches up scissors nicely.

Happy sewing.

Follow us on Facebook