In the mid sixties Singer was changing a great deal and freshened up the look of their machines with a sleeker body, and different controls, but underneath it was the same old dependable design you see in the 400 and 500 series machines. For the most part.

The Singer 611G looks virtually identical but differs in that it used a class 66 drop in bobbin while the revolutionary new 600 Touch and Sew, or Auto Reel had a bobbin that stayed in the machine, and wound in place.

At a glance it can be hard to tell these two machines apart unless you know what to look for, the 611G has a white cap on the upper guide and the top guide is plastic instead of metal.

Often derided as being unreliable, it was because aside from the auto winding feature, later versions of the T&S started to use plastic/nylon gears in the drive train and over time or through misadventure these broke.

The early models still used the same hand lapped metal gears, probably because Singer was still producing them for the other 6xx series machines and as yet, had not started their slow decline into mediocrity.

As a machinist I really appreciate the workmanship in these machines, the arm under the gear is part of the auto winding mechanism and in later models, these changed location and you guessed it, used more plastic.

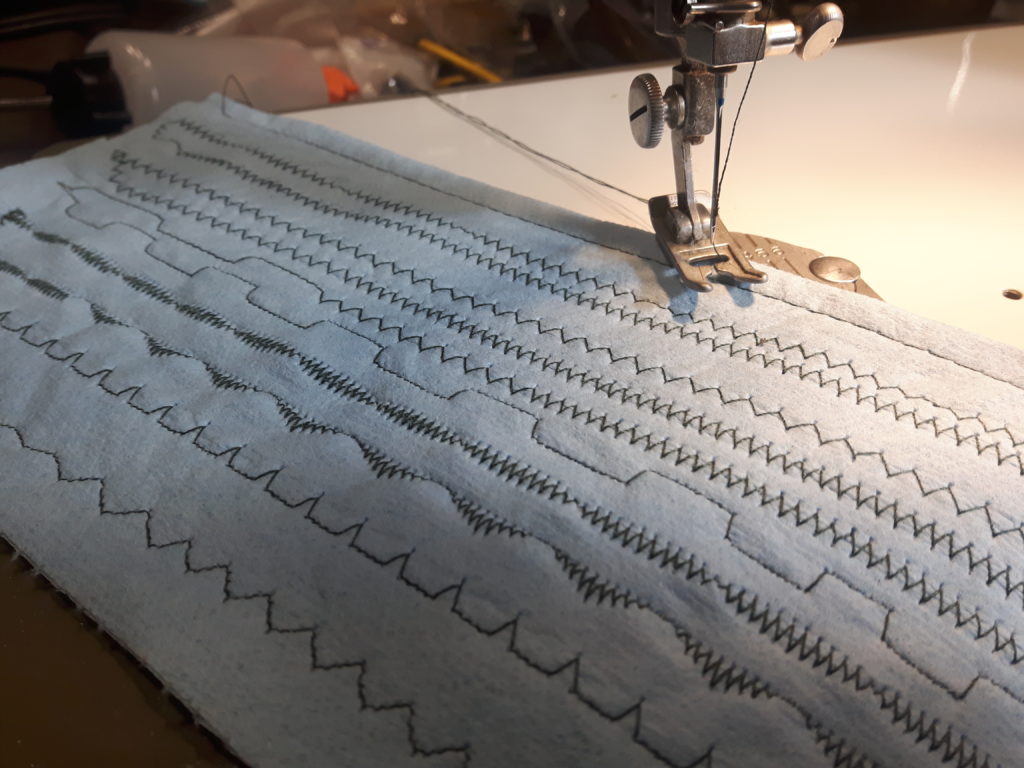

This early 600 will be joining our permanent collection as it is historically significant, and because it runs beautifully and makes a great stitch, in addition to being able to chain stitch which was a feature the T&S models made standard.

This machine might still outlast me…

We have several early Touch and Sew machines in the shop that are available, a 600e and a 626 Special which are both metal geared models, if you are interesting in adding one to your herd drop us a line.