The Pfaff 130 is regarded as one of the very best vintage machines due to it’s precise construction, smoothness, sewing speed (2500 stitches a minute), and ability to sew pretty much anything that you can fit under the foot. The motors were 1.3 amps to provide high speed and torque as the ceramic flywheel does not add much punching power.

This newly arrived 130 was and is still covered in a lot of old oil residue, that may also be nicotine, gas stove residue, and maybe even some 3 in 1 oil, which turns into shellac over time. This is why you should not use it for lubricating a machine as over time it will freeze them up solid.

After an initial wipe down with oil the machine looked a lot shinier and the plated parts that can be removed easily came off to go into the kerosene tank to soak. During the wipe down with oil a lot of brown crud was coming off the machine and in many cases this could be degraded clear coat, but due to the coating of crud on this machine we are pretty sure it is the same as the bright work.

Pfaff 130-6 with the tension unit and faceplate removed for cleaning, and looking very shiny after a wipe down with kerosene, which makes it look really shiny but once that dries you see how much crud is left on the head of the machine. 3 in 1 oil leaves a residue like this and one of the best ways to remove old 3 in 1 oil, is to use 3in1 oil as a cleaner as the matching solvent breaks down to old gummy residue.

It is a painstaking process to clean a machine like this, as you want to proceed carefully and remove small layers at a time to make sure the clearcoat is not compromised or starting to break down. We expect this machine to sparkle like a new penny and it will then be made available for sale, it has a lovely cabinet with a stool that stores inside.

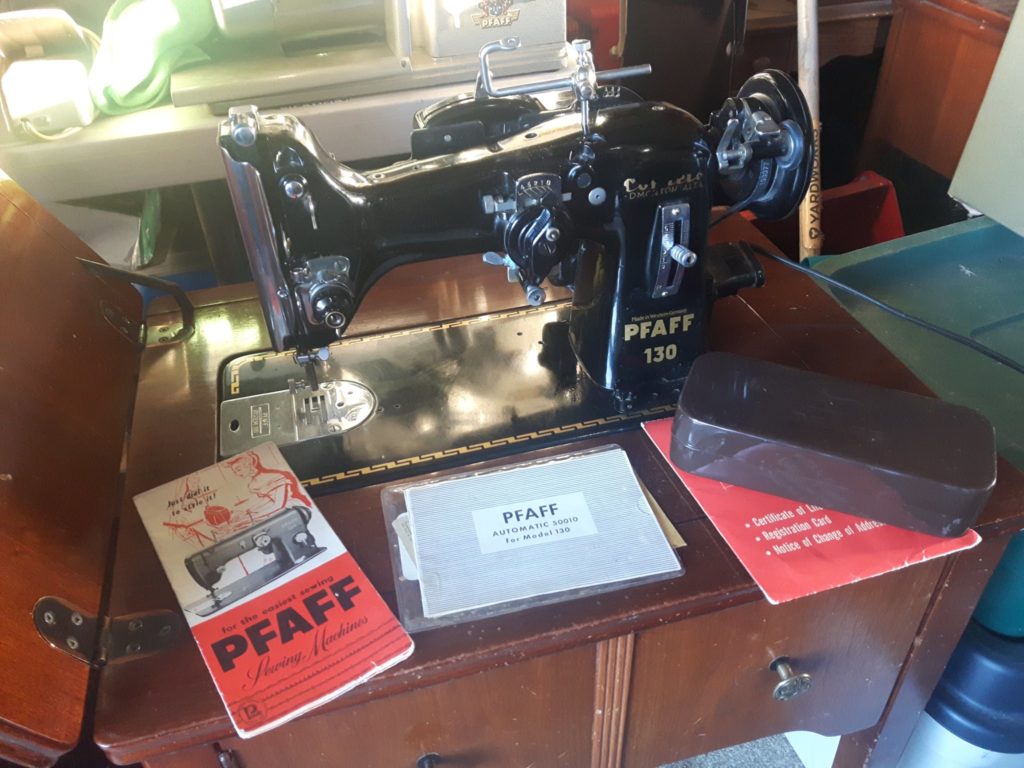

This is a Pfaff 130-6 we currently have available that has been restored cosmetically, electrically, and mechanically, and it has a very nice table, accessories, and all it’s original manuals. It also have the very desirable “coffee grinder” which is an attachment that adds extra decorative stitching.

Our price for this lovely example is $450.00 cad