Whenever I hear people say working on vintage sewing machines is easy, I ask them if they have ever worked on any of the Pfaff Automatics. ![]()

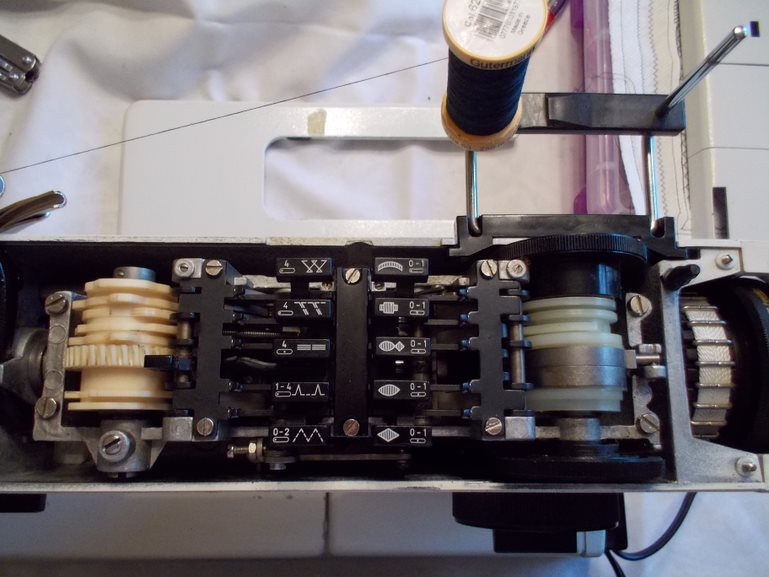

Removing the cam module on the 230/332 is fairly straightforward (unlike a Pfaff 1222) and this should be done for cleaning and lubrication as you cannot access the lower assemblies with this in place.

It is not difficult to remove the cam module as all you need to do is to remove the spring assembly (2 screws) and then remove the 4 big screws that hold the cam module in place. With that done you can clean the cam module with kerosene and then re-lubricate it with sewing oil.

Before removal make sure that you set the cam module to position 1, and do not engage the cam driver while it is out of the machine as you could throw out the cam positioning.

The rest of the moving assemblies should then be cleaned with kerosene and then re-lubricated with sewing oil, while adjustment to the needle position and zig zag are much more complicated and should be referred to a professional, unless you have very good mechanical skills and a service manual.

All in all, it is a superbly designed machine, the modular cam drive is genius, and I think I prefer working on cranky Pfaffs more than I like working on cranky Berninas.

If the machine is running well and just needs cleaning and lubrication it is a user friendly kind of job, this 230 runs like a top but the zig zag and needle position settings were all bit off.

My “mint” 332 recently had a similar over haul as the zig zag control was completely frozen and it required a lot of disassembly, cleaning, and reassembly before it would run and operate properly.

This is the heart of a 230/332 automatic and where all the magic happens, the cam module is driven by an eccentric roller on the main shaft whereas other companies like Singer, Bernina, Elna, and Husqvarna used gear driven cams.

Those Germans were always thinking out of the box and this system was used well into the seventies with the Pfaff 1222, although that cam module is much more complex and difficult to remove.

My recently acquired Pfaff 332 Automatic is almost “mint” but had been put away for 30 years, and the zig zag control was completely frozen, this should never be forced as you could break or dislodge the dial.

A full disassembly and service was done on this machine and now it is running perfectly, these are such a fast and smooth running machine and they make absolutely perfect stitches.

The Pfaff 1222e is a far more complex machine and also utilizes more electronics, this is a machine that is not for the faint of heart when it comes to servicing but again… it is a brilliantly designed machine.

Happy sewing.